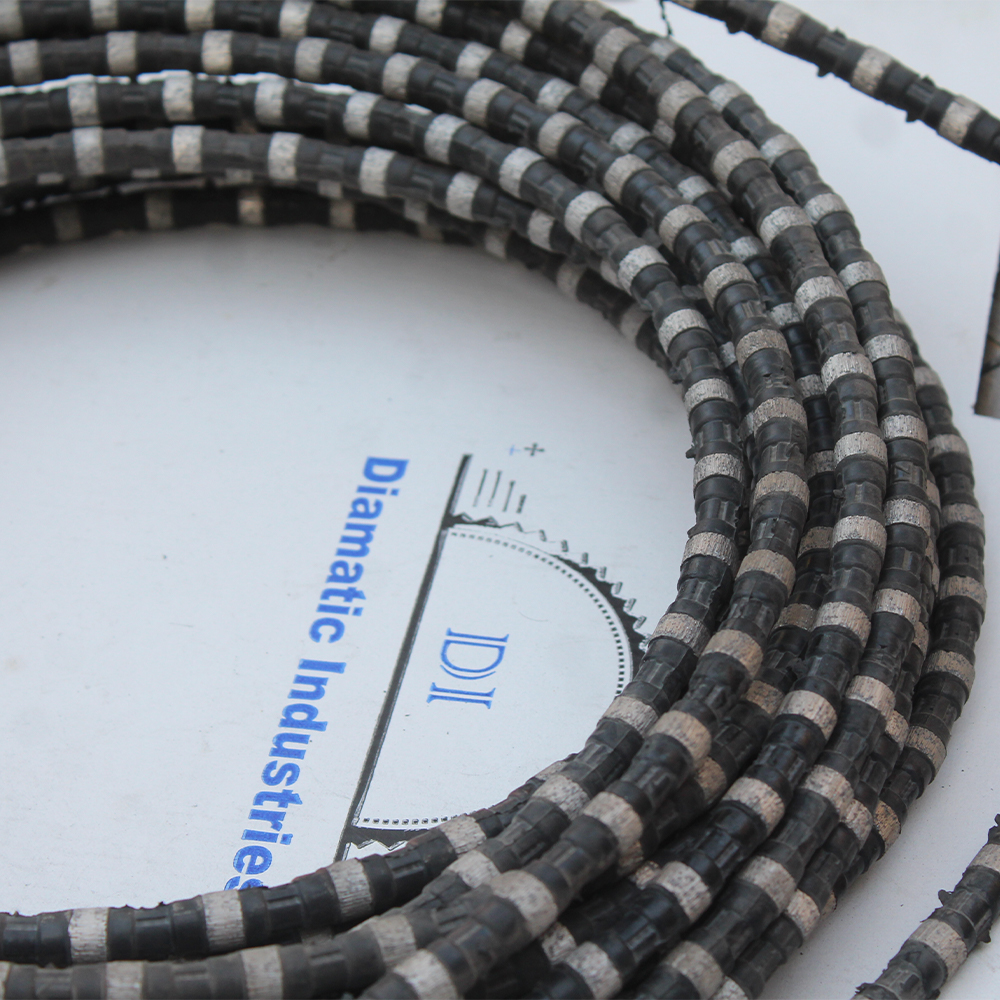

Manufacturing rubber-coated diamond wire with sintered beads, specifically designed for reinforced concrete cutting, involves a detailed process to ensure durability, flexibility, and optimal cutting performance. Here’s how such a diamond wire is typically manufactured.

| Item | Diameter (mm) | Rubber Coated | Concrete Type BEADS NO./M |

|---|---|---|---|

| Concrete | 11.4 | Spring + Rubber | Normal 38-40 |

| Reinforced Concrete | 11.4 | Spring + Rubber | Reinforced 38-40 |