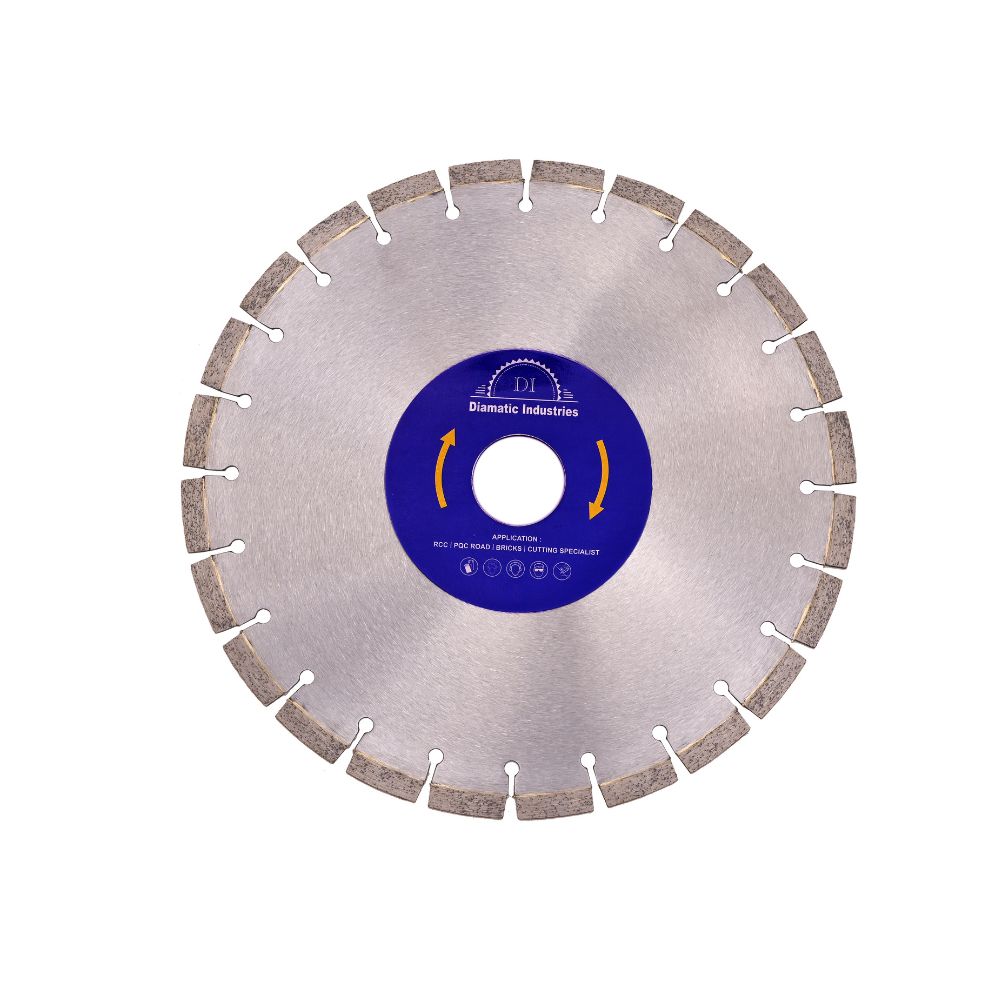

Smooth Cuts, Strong Foundations: PQC Joint Cutting Blades

It sounds like you're describing diamond saw blades designed specifically for cutting green concrete/Asphalt , emphasizing quality and tested raw materials. Diamond saw blades are known for their durability and effectiveness in cutting hard materials like concrete, especially when the concrete is still in its early, softer stage (referred to as green concrete).

Using high-quality raw materials in manufacturing ensures that the saw blades are robust and can withstand the demands of cutting concrete. Additionally, testing the raw materials ensures that they meet the necessary standards for strength and durability, crucial for maintaining the blade's performance over its lifespan.

| DIAMETER IN MM (INCH) | THICKNESS | BORE SIZE | DIAMOND SEGMENT HEIGHT | NO. OF SEGMENTS |

|---|---|---|---|---|

| 250 MM (10") | 3 MM | 25.4/50 MM | 10 MM | 21 |

| 300 MM (12") | 3 MM | 20/25.4/50 MM | 10 MM | 21 |

| 350 MM (14") | 3.2 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 4 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 5 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 6 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 8 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 10 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 12 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 350 MM (14") | 15 MM | 25.4/50 MM | 10MM/12MM | 25 |

| 400 MM (16") | 3.5 MM | 25.4/50 MM | 10MM/12MM | 28 |

| 400 MM (16") | 4 MM | 25.4/50 MM | 10MM/12MM | 28 |

| 400 MM (16") | 6 MM | 25.4/50 MM | 10MM/12MM | 28 |

| 400 MM (16") | 8 MM | 25.4/50 MM | 10MM/12MM | 28 |

| 450 MM (18") | 4 MM | 25.4/50 MM | 10MM/12MM | 30 |

| 450 MM (18") | 6 MM | 25.4/50 MM | 10MM/12MM | 30 |

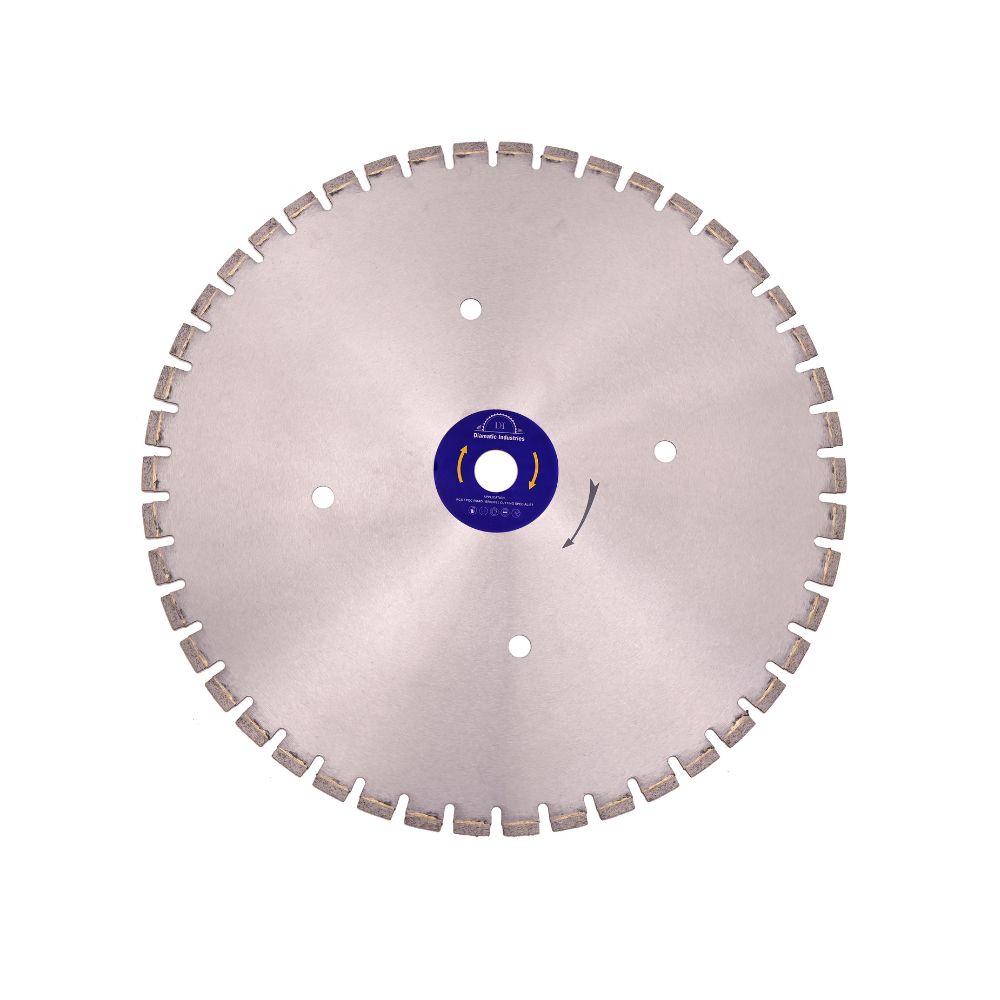

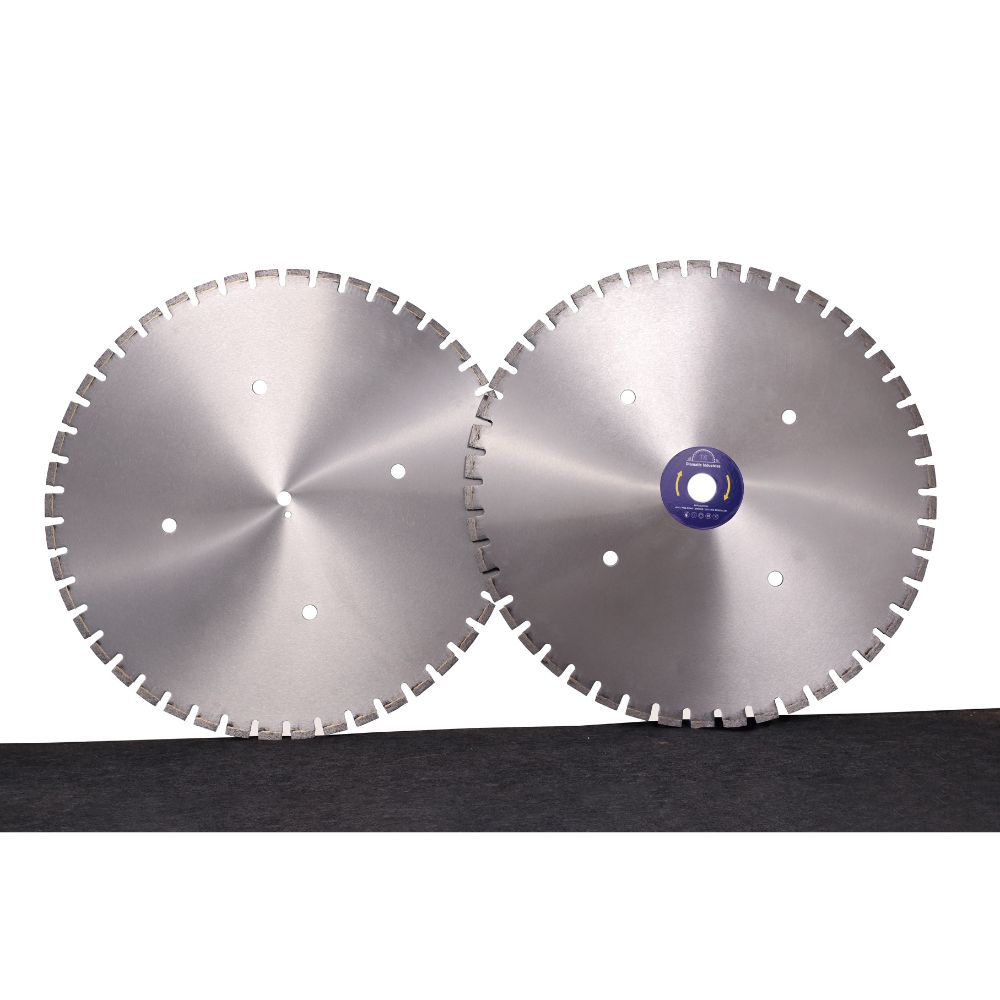

Diamond saw blades designed for cutting reinforced concrete, curb cutting, and refractory bricks typically utilize high-quality synthetic diamonds mixed with premium powders in their bonding material. This combination ensures superior performance and durability in demanding cutting applications:

| DIAMETER IN MM (INCH) | THICKNESS | BORE SIZE | DIAMOND SEGMENT HEIGHT | NO. OF SEGMENTS |

|---|---|---|---|---|

| 500 MM (20") | 4 MM | 25.4/50 MM | 10 MM/12 MM | 36 |

| 500 MM (20") | 5 MM | 50 MM | 10 MM/12 MM | 36 |

| 600 MM (24") | 4.2 MM | 25.4 MM | 10 MM/12 MM | 36 |

| 600 MM (24") | 5 MM | 50 MM | 10 MM/12 MM | 36 |

| 700 MM (28") | 5 MM | 50 MM | 10 MM/12 MM | 40 |

| 800 MM (32") | 4.5 MM | 25.4 MM | 10 MM/12 MM | 46 |

| 800 MM (32") | 6.5 MM | 50 MM | 10 MM/12 MM | 46 |

| 900 MM (36") | 7 MM | 100 MM | 10 MM/12 MM | 64 |

| 1000 MM (40") | 4.8 MM | 25.4 MM | 10 MM/12 MM | 64 |

| 1000 MM (40") | 7.5 MM | 100 MM | 10 MM/12 MM | 64 |

| 1200 MM (48") | 7.5 MM | 100 MM | 10 MM/12 MM | 74 |

| 1400 MM (56") | 8 MM | 100 MM | 10 MM/12 MM | 84 |

| 1500 MM (60") | 8 MM | 100 MM | 10 MM/12 MM | 84 |

| 1600 MM (64") | 8 MM | 100 MM | 10 MM/12 MM | 104 |

| 1800 MM (64") | 10 MM | 100 MM | 10 MM/12 MM | 120 |

| 2000 MM (80") | 10 MM | 100 MM | 10 MM/12 MM | 132 |